Five Key OSHA Standards for Work Platforms

Updated on December 8, 2020 (Previous update on May 30, 2017)

OSHA requirements for work platforms have always been incredibly complex. But since January 2017 when OSHA completely rewrote the standard 1910 Subpart D: Walking Working Surfaces (the standard that serves as the authority on work platform compliance), it's been nearly impossible to get a straight answer on what our fall protection needs to have to comply.

The OSHA standard for fall protection had been in dispute in the decades leading up to the January 2017 final ruling. The basics of the update established the requirement for employers to protect workers from fall hazards along unprotected sides or edges that are at least 4 feet above a lower level. It also established requirements for the performance, inspection, use, and maintenance of personal fall protection systems.

Here is a list of five current OSHA standards for work platforms that you may not be aware of

1. Any working surface 4 feet or higher must be protected with guardrails on all sides at least 42" tall and have to withstand 200 pounds of force.

OSHA 1910.29(b)(1): The top edge height of top rails, or equivalent guardrail system members, are 42 inches (107 cm), plus or minus 3 inches (8 cm), above the walking-working surface. The top edge height may exceed 45 inches (114 cm)

1910.29(b)(3): Guardrail systems are capable of withstanding, without failure, a force of at least 200 pounds (890 N) applied in a downward or outward direction within 2 inches (5 cm) of the top edge, at any point along the top rail.

This may be the quintessential OSHA requirement for work platforms. Any work area four feet or more above the next level lower MUST have guardrails. Period. The guardrails must be on every open side of the platform. In instances where the platform is up against another vertical surface (such as the tool being accessed), and the tool fully protects the opening, guardrails are not required on that side. In that case, it is still critical to ensure railing covers any gaps.

Don't forget: when you're performing manufacturing or maintenance tasks, there is a good chance you will be setting tools, parts, and hardware on the floor beside you. In order to prevent a wrench from falling off the platform and smacking a coworker on the head, 3-1/2" tall toeboards are required on all open sides of the platform (excluding openings). Guardrail systems should also be capable of withstanding 200 pounds of force applied in a downward or outward direction.

One important distinction of OSHA 1910 Subpart D is that a guardrail is what is on top of the platform, whereas a handrail is what is along the staircase. Handrails have a different height requirement than guardrails.

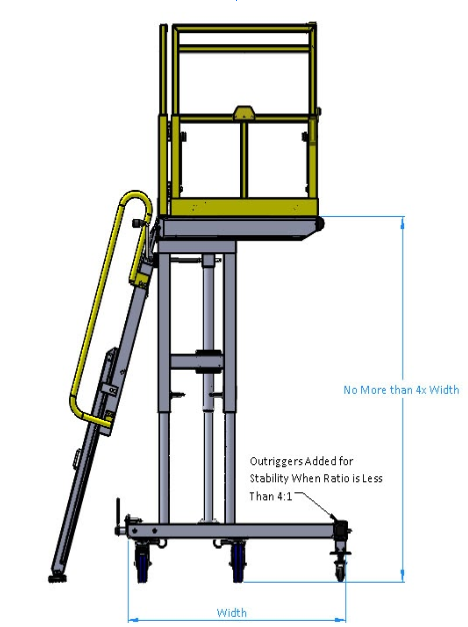

2. The platform's height cannot exceed 4x its base width without additional stabilizing support.

OSHA 1910.23(e)(1)(vi): The maximum work-surface height of mobile ladder stands and platforms does not exceed four times the shortest base dimension, without additional support. For greater heights, one must use outriggers, counterweights, or comparable means that stabilize the mobile ladder stands and platforms and prevent overturning.

If you need to access something at a great height but have limited space, consider requesting a stand with extended caster beams that can slide underneath your equipment and maintain this 4:1 ratio. These outriggers will provide enough of a base to keep your platform stable. Some companies even offer inboard outriggers which can lift up and over obstacles on your equipment, such as helicopter skids.

If you’re working in an area where extended caster beams at the base of the system are prohibited due to ground-level interference, counter-balance weights may be used to provide the stability required.

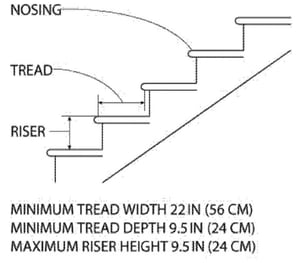

3. Stairs should have uniform step interval of no more than 9.5”, a tread depth of at least 9.5”, and a width of at least 22”.

OSHA 1910.23(e)(1): Mobile ladder stands and platforms have a step width of at least 16 inches (41 cm). Steps are uniformly spaced and arranged, with a rise of not more than 10 inches (25 cm) and a depth of not less than 7 inches (18 cm).

1910.25(b)(3): Stairs have uniform riser heights and tread depths between landings

1910.25(c)(2): Have a maximum riser height of 9.5 inches (24 cm)

1910.25(c)(3): Have a minimum tread depth of 9.5 inches (24 cm)

1910.25(c)(4): Have a minimum width of 22 inches (56 cm) between vertical barriers

While OSHA does not technically cover staircases that articulate (per 1910.25(a), articulate is defined as stairs that change pitch due to change in height at point of attachment),

Spika errs on the side of adhering to these standards with our designs.

The Spika-developed Variable-Pitch Staircase maintains a consistent step interval at any height, no matter if you have 2 feet or 12 feet of vertical travel. This design eliminates the old height adjustability method of having to crank the entire system up, resulting in a big step up to the bottom tread. High-traction tread provides slip-resistant traction while accessing the platform.

4. Self-closing safety gates are always required around openings (such as ladder holes), unless the opening is offset and nobody can fall directly through the hole.

OSHA 1910.29(b)(13): When guardrail systems are used around holes that serve as points of access (such as ladder ways), the guardrail system opening (b)(13)(i) has a self-closing gate that slides or swings away from the hole, and is equipped with a top rail and mid-rail or equivalent intermediate member, or (b)(13)(ii) is offset to prevent an employee from walking or falling into the hole.

Self-closing safety gates are critical for OSHA compliance; you have to ensure that your technicians cannot back through a hole in the guardrail or push the safety gate open without intending to. This is most commonly encountered at the top of ladders. Safety gates are often spring loaded and open inward then close behind you when you enter the platform. For extra safety precaution, consider using an interlock mechanism to ensure the safety gate cannot be opened when it's unsafe.

Self-closing safety gates are critical for OSHA compliance; you have to ensure that your technicians cannot back through a hole in the guardrail or push the safety gate open without intending to. This is most commonly encountered at the top of ladders. Safety gates are often spring loaded and open inward then close behind you when you enter the platform. For extra safety precaution, consider using an interlock mechanism to ensure the safety gate cannot be opened when it's unsafe.

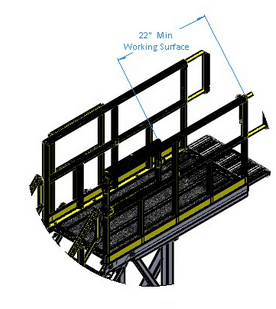

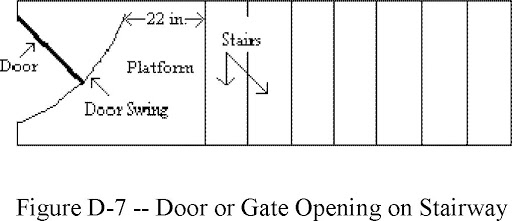

Staircases only require a safety gate when they are not attached to a platform (so there is inherent potential for the user to accidentally back up and fall down the stairs). In this instance, you must have 22” of clearance on the platform to allow the user to open the safety gate inward and be able to close it behind them.

1910.25(b)(5)(ii): When a door or a gate opens directly on a stairway, a platform is provided, and the swing of the door or gate does not reduce the platform’s effective usable depth to less than 22 inches (56 cm) for platforms installed on or after January 17, 2017.

While staircases that are connected to a larger platform do not require a safety gate, one may be added to your system if desired.

5. The platform must be capable of supporting at least four times its rated capacity.

OSHA 1910.23(e)(1)(iii): Mobile ladder stands and platforms are capable of supporting at least four times their maximum intended load.

Load rating requirements vary depending on the need and how many people/how much equipment will be on top of the system at a time. Regardless of if 800 pounds or 1600 pounds is required, the system will be designed to withstand 4x the rated load before failure. This is proven out through engineering analyses or physical load testing during the design and manufacturing process.

OSHA stipulates width/height ratio of 4:1 for work stand stability. This does not always account for tipping from external forces nor systems outside the ratio. To satisfy 1910.23(e)(1)(vi) for stabilizing the system by other means, we refer to a recognized standard for stability set forth in ANSI/SAIA A92.3-2006 (R2-14) Section 4.8.1/4.8.2. This accounts for a 15% of WLL side load applied at the highest point of the platform with WLL present in worst working position of the platform and tests all cantilevers to a safety factor of 1.5 WLL.

The number of safety standards that apply to work stands can be overwhelming. If you're unsure whether your platform is in compliance, ask the experts. It's not worth risking injuries, fines, and decreased employee morale, and often one little fix can bring you into full compliance.

Are you interested in seeing what your OSHA-compliant work platform by Spika could look like? Click on the button below.

For more information on employer deadlines, new terminology, and at-a-glance guidelines for mobile work platform compliance, download the checklist below.

Also check out these posts!